HY8:Inlet Configurations: Difference between revisions

From XMS Wiki

Jump to navigationJump to search

m (moved WMS:HY-8 Inlet Edge Conditions to WMS:HY-8 Inlet Configurations: Changed terminology in HY-8) |

No edit summary |

||

| Line 1: | Line 1: | ||

You can select from the following inlet | You can select from the following inlet configurations which are available according to the selected culvert shape. The following inlet conditions are available (see drawing), but may not apply to all shapes or materials: | ||

*Projecting | *Projecting | ||

| Line 16: | Line 16: | ||

{| Border=2 CellPadding=5 CellSpacing=2 | {| Border=2 CellPadding=5 CellSpacing=2 | ||

|- | |- | ||

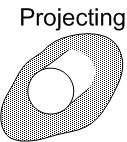

| Width=263 Align=Center | [[Image:HY8Projecting.jpg]] || Width=130 Valign=Center | This | | Width=263 Align=Center | [[Image:HY8Projecting.jpg]] || Width=130 Valign=Center | This configuration results in the end of the culvert barrel projecting out of the embankment. | ||

|- | |- | ||

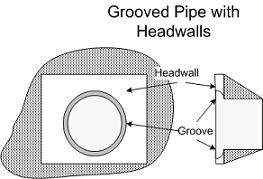

| Align=Center | [[Image:HY8GroovedHeadWall(FINAL).JPG]] || Valign=Center | The grooved pipe is for concrete culverts and decreases the loss through the culvert entrance. | | Align=Center | [[Image:HY8GroovedHeadWall(FINAL).JPG]] || Valign=Center | The grooved pipe is for concrete culverts and decreases the loss through the culvert entrance. | ||

Revision as of 20:35, 28 July 2011

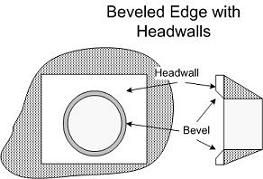

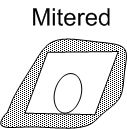

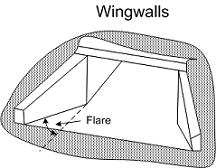

You can select from the following inlet configurations which are available according to the selected culvert shape. The following inlet conditions are available (see drawing), but may not apply to all shapes or materials:

- Projecting

- Grooved end with headwall (0.05 X 0.07D)

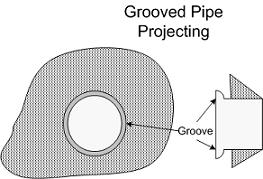

- Grooved end projecting (0.05 X 0.07D)

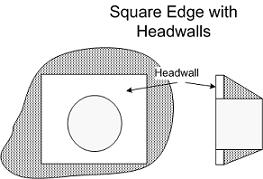

- Square edge with headwall

- Beveled

- Mitered to conform with fill slope

- Headwall

The user can select only one inlet condition for each culvert. Detailed explanations of these inlet conditions can be found in FHWA Publication HDS No. 5 (2001) bundled with the program.

- NOTE: HDS-5 notes that "Flared end sections made of either metal or concrete, are the sections commonly available from manufacturers. From limited hydraulic tests they are equivalent in operation to a headwall in both inlet and outlet control. Some end sections, incorporating a closed taper in their design have a superior hydraulic performance. These latter sections can be designed using the information given for the beveled inlet"