SMS:SRH-2D Errors: Difference between revisions

| (30 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

This is a list of known error messages produced by [[SMS:SRH-2D|SRH-2D]]. These errors will appear during the model run. | This is a list of common known error messages produced by [[SMS:SRH-2D|SRH-2D]]. This is not a comprehensive list of all possible errors. These errors will appear during the model run. | ||

:'''''NOTE: To search this web page, use CTRL+F''''' | :'''''NOTE: To search this web page, use CTRL+F''''' | ||

| Line 14: | Line 14: | ||

* ''Error Code'' gives the Error Code (if any). | * ''Error Code'' gives the Error Code (if any). | ||

* ''Error Text from Model'' gives the full text of the error message. Errors that do not produce any error text will have "no text" in this field. | * ''Error Text from Model'' gives the full text of the error message. Errors that do not produce any error text will have "no text" in this field. | ||

* ''Affected Model Component'' gives the component(s) in the model which is most likely causing the error and will need review/adjustment for the simulation to run correctly. | |||

* ''Description'' gives more details about the error. | * ''Description'' gives more details about the error. | ||

* ''Potential Solution'' gives steps that may be necessary to correct the issue. | * ''Potential Solution'' gives steps that may be necessary to correct the issue. | ||

| Line 25: | Line 26: | ||

! style="width:5%;" | Error Code | ! style="width:5%;" | Error Code | ||

! style="width:25%;" | Error Text from Model | ! style="width:25%;" | Error Text from Model | ||

! ! style="width:5%;" | Affected Model Component | |||

! style="width:25%;" class="unsortable" | Description | ! style="width:25%;" class="unsortable" | Description | ||

! style="width: | ! style="width:35%;" class="unsortable" | Potential Solution | ||

<!-- Use the following as a template to add new entries | <!-- Use the following as a template to add new entries | ||

|- | |- | ||

| Line 32: | Line 34: | ||

| code | | code | ||

| text | | text | ||

| component | |||

| description | | description | ||

| solution | | solution | ||

| Line 39: | Line 42: | ||

| 1 | | 1 | ||

| Stopped in spline.f90 H | | Stopped in spline.f90 H | ||

| Time series data used to define inflows/outflows | | BC Coverage, Materials Coverage | ||

| Time series data used to define inflows/outflows, time varying water surface elevations, or time varying roughness has issues with how it is defined, such as duplicate times. | |||

| The time series data should only have one data value per defined time. Review the ''XY Series Editor'' where the time series data is defined for the boundary conditions and remove any duplicate time entries. | | The time series data should only have one data value per defined time. Review the ''XY Series Editor'' where the time series data is defined for the boundary conditions and remove any duplicate time entries. | ||

|- | |- | ||

| SRH-2D | | SRH-2D | ||

| 1 | | 1 | ||

| Stopped in uti_qwin_xyplot.f90 TIME_SIMU | | Stopped in uti_qwin_xyplot.f90 TIME_SIMU | ||

| Model Control | |||

| Inconsistent time control settings. | | Inconsistent time control settings. | ||

| The end time is prior to the start time in the model control. Adjust so the end time is later than the start time. | | The end time is prior to the start time in the model control. Adjust so the end time is later than the start time. | ||

| Line 51: | Line 56: | ||

| | | | ||

| No cells cover an obstruction in structure_obstruction.f90 | | No cells cover an obstruction in structure_obstruction.f90 | ||

| Obstruction Coverage | |||

| Obstruction feature area of influence does not cover the centroid of at least one element. | | Obstruction feature area of influence does not cover the centroid of at least one element. | ||

| The "Obstruction Width/Diameter:" value in the ''Obstructions Properties'' dialog is set to "0" and/or an obstruction arc is positioned just beyond half the width/diameter defined in the properties from the centroid of a mesh element. | | The "Obstruction Width/Diameter:" value in the ''Obstructions Properties'' dialog is set to "0" and/or an obstruction arc is positioned just beyond half the width/diameter defined in the properties from the centroid of a mesh element. | ||

| Line 57: | Line 63: | ||

| 5 | | 5 | ||

| Stopped in structure_culvert.f90 ICELL error#5 | | Stopped in structure_culvert.f90 ICELL error#5 | ||

| Material Coverage | |||

| Boundary condition arc mesh snapping does not match inactive material zone snapping. | | Boundary condition arc mesh snapping does not match inactive material zone snapping. | ||

| <!--In SMS v12.1, some paired arc 1D structures require an "unassigned" material zone between the structure arcs. If the material zone snapping does not match the BC arc snapping, there will be element inactivity problems at the face of the structure. Modify the placement of the structure arcs in the boundary condition coverage or unassigned material polygon edges so that the snap preview of the material polygon matches the snap preview of the structure arc. In SMS 12.2 or later, it is not necessary to create the unassigned material polygon to disable the area between the structure arcs because SRH-2D has been modified to do this internally. If encountering this error using 12.2 or later, one possible solution would be to delete the unassigned material polygon, rebuild polygons and double check all polygons to make sure valid material types have been assigned.-->Review the material polygon snapping and review material assignment. | | <!--In SMS v12.1, some paired arc 1D structures require an "unassigned" material zone between the structure arcs. If the material zone snapping does not match the BC arc snapping, there will be element inactivity problems at the face of the structure. Modify the placement of the structure arcs in the boundary condition coverage or unassigned material polygon edges so that the snap preview of the material polygon matches the snap preview of the structure arc. In SMS 12.2 or later, it is not necessary to create the unassigned material polygon to disable the area between the structure arcs because SRH-2D has been modified to do this internally. If encountering this error using 12.2 or later, one possible solution would be to delete the unassigned material polygon, rebuild polygons and double check all polygons to make sure valid material types have been assigned.-->Review the material polygon snapping and review material assignment. | ||

|- | |||

| SRH-2D | |||

| 5 | |||

| Stopped in structure_culvert.f90 ICELL | |||

| Boundary Condition Coverage | |||

| HY-8 arc pairs are not lining up with each other. | |||

| Review the arcs for the culverts. Verify that the arcs are correctly paired and drawn in the same direction. | |||

|- | |- | ||

| SRH-2D | | SRH-2D | ||

| | | | ||

| None | | None | ||

| More than 99 obstructions exist | | Obstruction Coverage | ||

| More than 99 obstructions exist in the project. | |||

| SRH-2D has a built in limit to how many obstructions can be included in a model. Currently this limit is 99. Reduce the number of obstructions to 99 or fewer. | | SRH-2D has a built in limit to how many obstructions can be included in a model. Currently this limit is 99. Reduce the number of obstructions to 99 or fewer. | ||

<!--|- | <!--|- | ||

| Line 75: | Line 90: | ||

| 2 | | 2 | ||

| ALL INLET cells are dry from bc_mdot2.f90! Code may have blow up due to input errors or too-large time step. | | ALL INLET cells are dry from bc_mdot2.f90! Code may have blow up due to input errors or too-large time step. | ||

| Material Coverage | |||

| Material polygons near inflow are unassigned. This occurs when the material coverage has not been linked to the simulation. Also occurs when all material polygons covering the inflow BC have an "unassigned" material type. This can also occur if no boundary conditions providing an inflow source have been included in the simulation. | | Material polygons near inflow are unassigned. This occurs when the material coverage has not been linked to the simulation. Also occurs when all material polygons covering the inflow BC have an "unassigned" material type. This can also occur if no boundary conditions providing an inflow source have been included in the simulation. | ||

| Review the simulation to make certain materials have been assigned and that materials and BC coverages have been added to the simulation. | | Review the simulation to make certain materials have been assigned and that materials and BC coverages have been added to the simulation. | ||

| Line 81: | Line 97: | ||

| | | | ||

| FATAL ERROR The code diverged; further reduction of time step would help the convergence! | | FATAL ERROR The code diverged; further reduction of time step would help the convergence! | ||

| Model Control | |||

| Too large of a time step. | | Too large of a time step. | ||

| Reduce the size of the computational time step in the model control. | | Reduce the size of the computational time step in the model control. | ||

| Line 87: | Line 104: | ||

| 3 | | 3 | ||

| bad mesh ! Stopped in indx_conn.f | | bad mesh ! Stopped in indx_conn.f | ||

| 2D Mesh | |||

| Problem in mesh, often due to overlapping elements. | | Problem in mesh, often due to overlapping elements. | ||

| Check if problem cell (element) id is listed. Otherwise, examine mesh quality in SMS. | | Check if problem cell (element) id is listed. Otherwise, examine mesh quality in SMS. | ||

| Line 93: | Line 111: | ||

| 0 | | 0 | ||

| Exit code 0 | | Exit code 0 | ||

| Varies | |||

| The SRH-2D simulation has stopped or finished whether successfully executed or not. | | The SRH-2D simulation has stopped or finished whether successfully executed or not. | ||

| Review the simulation results, if any. Further troubleshooting may be required if there are no solutions data or the data is incomplete. | | Review the simulation results, if any. Further troubleshooting may be required if there are no solutions data or the data is incomplete. | ||

| Line 99: | Line 118: | ||

| 8 | | 8 | ||

| Inconsistent cell ID in mesh_connectivity: maybe due to wrong nodestring | | Inconsistent cell ID in mesh_connectivity: maybe due to wrong nodestring | ||

| 2D Mesh, BC Coverage | |||

| There is an issue with how the BC arcs are being assigned to the mesh elements. | | There is an issue with how the BC arcs are being assigned to the mesh elements. | ||

| Review mesh for overlapping elements. Also, check snapping of BC arcs. | | Review mesh for overlapping elements. Also, check snapping of BC arcs. | ||

| Line 118: | Line 138: | ||

in casename.GRD file are: 15459 8277 23735 47225<br> | in casename.GRD file are: 15459 8277 23735 47225<br> | ||

Mesh topology has to be the same for irest>=1 or init_method=3 | Mesh topology has to be the same for irest>=1 or init_method=3 | ||

| Model Control | |||

| Using a restart file that was created with another mesh. Restart files can only be used with simulations using the exact same mesh. | | Using a restart file that was created with another mesh. Restart files can only be used with simulations using the exact same mesh. | ||

| Review the restart file and use a restart that matches the mesh. Regenerate the restart file if needed or select a different initial condition option. | | Review the restart file and use a restart that matches the mesh. Regenerate the restart file if needed or select a different initial condition option. | ||

| Line 124: | Line 145: | ||

| 6940 | | 6940 | ||

| None | | None | ||

| Material Coverage | |||

| The assigned material types for the areas upstream or downstream of the culvert location are not valid. | | The assigned material types for the areas upstream or downstream of the culvert location are not valid. | ||

| Ensure that areas upstream of the upstream culvert location and areas downstream of the downstream culvert location have a valid material type assigned. | | Ensure that areas upstream of the upstream culvert location and areas downstream of the downstream culvert location have a valid material type assigned. | ||

| Line 130: | Line 152: | ||

| 1 | | 1 | ||

| Stopped in structure_pressure_flow.f90 PARA DISTANCE | | Stopped in structure_pressure_flow.f90 PARA DISTANCE | ||

| 2D Mesh, BC Coverage | |||

| Shape of pressure zone is not acceptable for a parabolic type bridge ceiling. | | Shape of pressure zone is not acceptable for a parabolic type bridge ceiling. | ||

| Ensure that the pressure zone, between the pressure flow arcs, is rectangular in shape. | | Ensure that the pressure zone, between the pressure flow arcs, is rectangular in shape. | ||

| Line 138: | Line 161: | ||

Wrong IFACE matching occurred in structure_internal.f90 #4 | Wrong IFACE matching occurred in structure_internal.f90 #4 | ||

Error Code is: 9669 | Error Code is: 9669 | ||

| 2D Mesh, BC Coverage | |||

| The area between the pressure zone arcs with overtopping turned on is not rectangular in shape and/or that the elements in-between the arcs are not rectangular. | | The area between the pressure zone arcs with overtopping turned on is not rectangular in shape and/or that the elements in-between the arcs are not rectangular. | ||

| Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). If necessary, create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. | | Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). If necessary, create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. | ||

| Line 147: | Line 171: | ||

Wrong IFACE matching occurred in structure_internal.f90 #4 | Wrong IFACE matching occurred in structure_internal.f90 #4 | ||

Error Code is: 46631 | Error Code is: 46631 | ||

| 2D Mesh | |||

| Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). | | Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). | ||

| Create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. | | Create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. | ||

| Line 156: | Line 181: | ||

Wrong IFACE matching occurred in structure_internal.f90 #4 | Wrong IFACE matching occurred in structure_internal.f90 #4 | ||

Error Code is: 0 | Error Code is: 0 | ||

| BC Coverage | |||

| There is an issue with one or more boundary condition arc definitions. | | There is an issue with one or more boundary condition arc definitions. | ||

| Review snap preview of boundary condition arcs. | | Review snap preview of boundary condition arcs. | ||

| Line 164: | Line 190: | ||

A downstream Structure nodestring has not set right; structure_culvert.f90 ICELL error#2 | A downstream Structure nodestring has not set right; structure_culvert.f90 ICELL error#2 | ||

Error Code is: 16026 | Error Code is: 16026 | ||

| 2D Mesh | |||

| The 2D mesh around and through the structure is not optimal. | | The 2D mesh around and through the structure is not optimal. | ||

| Examine the areas around the structure. Suggestions to optimize the mesh around the structure include creating patched (quadrilateral) elements through the structure from one face to the other. <!--SRH-2D inactivates elements between the structure faces where the 1D flow is computed. Creating quadrilateral elements in the zone between the faces facilitates the process SRH uses to locate and inactivate the flow computations for those elements in the mesh. Configure the mesh such that the structure faces can be created alone a series of element edges that are oriented in the same direction (along a flat and straight line of element edges).--> | | Examine the areas around the structure. Suggestions to optimize the mesh around the structure include creating patched (quadrilateral) elements through the structure from one face to the other. <!--SRH-2D inactivates elements between the structure faces where the 1D flow is computed. Creating quadrilateral elements in the zone between the faces facilitates the process SRH uses to locate and inactivate the flow computations for those elements in the mesh. Configure the mesh such that the structure faces can be created alone a series of element edges that are oriented in the same direction (along a flat and straight line of element edges).--> | ||

| Line 172: | Line 199: | ||

Tailwater WSE exceeded the maximum TW in the Reverse HY8 Table structure_hy8.f90 | Tailwater WSE exceeded the maximum TW in the Reverse HY8 Table structure_hy8.f90 | ||

Error Code is: 79 | Error Code is: 79 | ||

| 2D Mesh, Model Control | |||

| Computed water surface elevations near the culvert became extremely high. This could be from too large of a time step, poor mesh quality near the culvert faces, or parts of the mesh were the culvert is applied have higher elevations than what are defined as the inverts defined in the HY-8 culvert definition | | Computed water surface elevations near the culvert became extremely high. This could be from too large of a time step, poor mesh quality near the culvert faces, or parts of the mesh were the culvert is applied have higher elevations than what are defined as the inverts defined in the HY-8 culvert definition | ||

| Review mesh quality near the culvert face. Check to ensure that mesh node elevations where culvert faces are applied do not exceed invert elevations as defined in the HY-8 culvert definition. Lowering the time step to improve stability around the culvert could also help. | | Review mesh quality near the culvert face. Check to ensure that mesh node elevations where culvert faces are applied do not exceed invert elevations as defined in the HY-8 culvert definition. Lowering the time step to improve stability around the culvert could also help. | ||

| Line 178: | Line 206: | ||

| N/A | | N/A | ||

| forrtl: severe (24): end-of-file during read, unit n, file {your filepath.dat} Image PC Routine Line Source srh2d_3.2_quickwi...Unknown... | | forrtl: severe (24): end-of-file during read, unit n, file {your filepath.dat} Image PC Routine Line Source srh2d_3.2_quickwi...Unknown... | ||

| Varies | |||

| This is usually a generic error indicating something is wrong with the SRH-2D simulation casename.DAT file created by SRH pre. It typically signifies that SRH-Pre did not terminate normally and generate a valid simulation file. The cause of the error could be any number of issues. | | This is usually a generic error indicating something is wrong with the SRH-2D simulation casename.DAT file created by SRH pre. It typically signifies that SRH-Pre did not terminate normally and generate a valid simulation file. The cause of the error could be any number of issues. | ||

| Check for any error messages reported by SRH-pre by going to the SMS model wrapper and clicking on the "PreSRH-2D" line and reviewing the on screen output messages. | | Check for any error messages reported by SRH-pre by going to the SMS model wrapper and clicking on the "PreSRH-2D" line and reviewing the on screen output messages. | ||

| Line 184: | Line 213: | ||

| 1 | | 1 | ||

| Program stopped due to the following: Stopped in read_input2: Mismatch in HY8 ID | | Program stopped due to the following: Stopped in read_input2: Mismatch in HY8 ID | ||

| | |||

| This is a bug in SRH caused by having two culvert crossings defined in the *.hy8 crossing file with certain similarities in their names. | | This is a bug in SRH caused by having two culvert crossings defined in the *.hy8 crossing file with certain similarities in their names. | ||

| The temporary workaround until this is fixed is to make all crossing names as different as possible, including the first character of the names. For example, "My Culvert" and "My Culvert1" could cause this error. Change one of the crossings to make it different, something like "My Culvert" and "Two Barrel Wingwall" would resolve the issue.--> | | The temporary workaround until this is fixed is to make all crossing names as different as possible, including the first character of the names. For example, "My Culvert" and "My Culvert1" could cause this error. Change one of the crossings to make it different, something like "My Culvert" and "Two Barrel Wingwall" would resolve the issue.--> | ||

| Line 190: | Line 220: | ||

| N/A | | N/A | ||

| Failed to find a mesh cell which contains the following (x y) points: (X,Y)= | | Failed to find a mesh cell which contains the following (x y) points: (X,Y)= | ||

| 2D Mesh | |||

| This is caused when there is a void added to the mesh by deleting a mesh element from the mesh after the mesh has been generated. Creating void by deleting mesh elements may not actually remove the element data from the mesh in SRH-2D. | | This is caused when there is a void added to the mesh by deleting a mesh element from the mesh after the mesh has been generated. Creating void by deleting mesh elements may not actually remove the element data from the mesh in SRH-2D. | ||

|If a void is needed in the mesh, it should be created as a polygon in the Mesh Generator coverage and given a mesh type of "None". When a mesh is generated using polygons with the "None" type, a void will be created in the mesh that can be recognized by SRH-2D. | |If a void is needed in the mesh, it should be created as a polygon in the Mesh Generator coverage and given a mesh type of "None". When a mesh is generated using polygons with the "None" type, a void will be created in the mesh that can be recognized by SRH-2D. | ||

| Line 196: | Line 227: | ||

| 0 | | 0 | ||

| Program stopped due to the following: IFACE match does not found in structure_culvert.f90 #''n'' | | Program stopped due to the following: IFACE match does not found in structure_culvert.f90 #''n'' | ||

| 2D Mesh | |||

| Element configuration around the structure face is causing a mismatch in the transition into or out of the structure. | | Element configuration around the structure face is causing a mismatch in the transition into or out of the structure. | ||

| It may help to ensure all elements within the two structures are quadrilateral elements. It may also help to ensure that the first row of elements downstream of the downstream structure face and upstream of the upstream structure face are also quadrilateral elements that are "well formed" ("Well formed" elements as in having interior corners as close to 90 degrees as possible). | | It may help to ensure all elements within the two structures are quadrilateral elements. It may also help to ensure that the first row of elements downstream of the downstream structure face and upstream of the upstream structure face are also quadrilateral elements that are "well formed" ("Well formed" elements as in having interior corners as close to 90 degrees as possible). | ||

| Line 202: | Line 234: | ||

| 1 | | 1 | ||

| Program stopped due to the following: Stopped in read_input2.f90 HY8 Forward_TABLE Line Error | | Program stopped due to the following: Stopped in read_input2.f90 HY8 Forward_TABLE Line Error | ||

| Files | |||

| There is a problem reading the culvert table file. One of the causes of this is that the HY-8 file containing the culvert definition does not include a file extension. | | There is a problem reading the culvert table file. One of the causes of this is that the HY-8 file containing the culvert definition does not include a file extension. | ||

| Add a ".hy8" file extension to the culvert definition | | Add a ".hy8" file extension to the culvert definition file name. | ||

|- | |- | ||

|SRH-2D | |SRH-2D | ||

|N/A | |N/A | ||

|forrtl: severe (170): Program Exception - stack overflow | |forrtl: severe (170): Program Exception - stack overflow | ||

| 2D Mesh | |||

|The simulation is too large for SRH-2D to process. Typically this occurs when running a simulation using sediment transport and a 2D mesh that contains more than 50,000 elements. | |The simulation is too large for SRH-2D to process. Typically this occurs when running a simulation using sediment transport and a 2D mesh that contains more than 50,000 elements. | ||

|Reduce the number of elements in the 2D mesh and try running the simulation again. | |Reduce the number of elements in the 2D mesh and try running the simulation again. | ||

| Line 214: | Line 248: | ||

| 3 | | 3 | ||

| Not ready in solve.f90 SEDIMENT MODULE | | Not ready in solve.f90 SEDIMENT MODULE | ||

| Model Control, BC Coverage | |||

| This errors occurs when sediment transport is being modeled in a project containing 1D hydraulic structures (culverts, weirs, pressure bridges, etc.). SRH-2D cannot model sediment transport in models containing 1D hydraulic structures. | | This errors occurs when sediment transport is being modeled in a project containing 1D hydraulic structures (culverts, weirs, pressure bridges, etc.). SRH-2D cannot model sediment transport in models containing 1D hydraulic structures. | ||

| Either do not use the sediment transport in the model run, or remove the 1D hydraulic structures from the model. | | Either do not use the sediment transport in the model run, or remove the 1D hydraulic structures from the model. | ||

| Line 220: | Line 255: | ||

| 1 | | 1 | ||

| Program stopped due to the following: Wrong Boundary ID;may due to some boundary mesh points are not in NODESTRING lists in SMS | | Program stopped due to the following: Wrong Boundary ID;may due to some boundary mesh points are not in NODESTRING lists in SMS | ||

| 2D Mesh | |||

| This error seems to be related to issues with mesh quality. | | This error seems to be related to issues with mesh quality. | ||

| Review mesh quality. Check for elements with very small or very large interior angles (angles less than 10 degrees or greater than 180 degrees. If any are present, make adjustments in the conceptual model (mesh generator coverage) and re-generate the mesh. | | Review mesh quality. Check for elements with very small or very large interior angles (angles less than 10 degrees or greater than 180 degrees. If any are present, make adjustments in the conceptual model (mesh generator coverage) and re-generate the mesh. | ||

| Line 226: | Line 262: | ||

| 67 | | 67 | ||

| Input statement requires too much data, unit 1 | | Input statement requires too much data, unit 1 | ||

| Model Control | |||

| This error appears related to using a restart file that doesn't match the project geometry. | | This error appears related to using a restart file that doesn't match the project geometry. | ||

| Review the restart file. Common issues appear to be using a restart file that came from a different project or uses a different projection. Check that all major aspects of the project geometry (mesh, nodes, units, coordinate system) match what is used in the project in order to use a restart file. The other solution is to not use a restart file with the simulation and select another option for the initial condition. | | Review the restart file. Common issues appear to be using a restart file that came from a different project or uses a different projection. Check that all major aspects of the project geometry (mesh, nodes, units, coordinate system) match what is used in the project in order to use a restart file. The other solution is to not use a restart file with the simulation and select another option for the initial condition. | ||

| Line 232: | Line 269: | ||

| 7 | | 7 | ||

| Inconsistent cell ID in mesh_connectivity.f90: maybe wrong nodestring | | Inconsistent cell ID in mesh_connectivity.f90: maybe wrong nodestring | ||

| BC Coverage | |||

| This error is caused when two arcs in the boundary condition coverage snap to the same nodes but have different boundary condition types. | | This error is caused when two arcs in the boundary condition coverage snap to the same nodes but have different boundary condition types. | ||

| Review the boundary condition arcs and use the snap preview. | | Review the boundary condition arcs and use the snap preview. | ||

|- | |||

| SRH-2D | |||

| 16 | |||

| Linked Pair nodestring direction is wrong; please reverse them. | |||

| BC Coverage | |||

| This error is caused when a paired arc structure, such as a culvert, has arcs that have been drawn in opposite directions or the arcs are not facing downstream. | |||

| Review a paired arc structures to ensure that the arcs are post going the same direction and that the arcs are facing downstream. Fix any structure arcs that are going the wrong direction. | |||

|- | |||

| SRH-2D | |||

| 4 | |||

| Program stopped due to the following: The upstream INTERNAL boundary linked to a downstream should a water withdrawal! | |||

| BC coverage or 2D mesh | |||

| This indicates a model instability near a boundary condition arc. Review 2D mesh elements near BC arcs and/or adjust BC coverage values. | |||

|} | |} | ||

| Line 244: | Line 295: | ||

! style="width:5%;" | Error Code | ! style="width:5%;" | Error Code | ||

! style="width:25%;" | Error Text from Model | ! style="width:25%;" | Error Text from Model | ||

! style="width:5%;" | Affected Model Component | |||

! style="width:25%;" class="unsortable" | Description | ! style="width:25%;" class="unsortable" | Description | ||

! style="width: | ! style="width:35%;" class="unsortable" | Potential Solution | ||

<!-- Use the following as a template to add new entries | <!-- Use the following as a template to add new entries | ||

|- | |- | ||

| Line 258: | Line 310: | ||

| 1 | | 1 | ||

| unable to open srhhydro file! | | unable to open srhhydro file! | ||

| Files | |||

| Unable to open the exported srhhydro file. | | Unable to open the exported srhhydro file. | ||

| The path length for the SMS project is too long. Therefore, the SRH-2D preprocessor could not read the exported files from SMS. Reduce the path length to less than 300 characters. | | The path length for the SMS project is too long. Therefore, the SRH-2D preprocessor could not read the exported files from SMS. Reduce the path length to less than 300 characters. | ||

| Line 264: | Line 317: | ||

| 1 | | 1 | ||

| Element ID is not consecutive | | Element ID is not consecutive | ||

| 2D Mesh | |||

| The mesh element ID's have been mismatched since some mesh nodes were modified and not renumbered. | | The mesh element ID's have been mismatched since some mesh nodes were modified and not renumbered. | ||

| Renumber the mesh nodes using the '''Renumber''' command under the ''Nodes'' menu in the Mesh module. | | Renumber the mesh nodes using the '''Renumber''' command under the ''Nodes'' menu in the Mesh module. | ||

| Line 272: | Line 326: | ||

Two points are: xx xx<br> | Two points are: xx xx<br> | ||

Check the mesh node list; do this using _SIF.dat file directly! | Check the mesh node list; do this using _SIF.dat file directly! | ||

| Monitor Coverage | |||

| Monitor line spans a void or hole in the mesh. | | Monitor line spans a void or hole in the mesh. | ||

| Reconfigure the monitor line. Monitor lines cannot span holes in the mesh. | | Reconfigure the monitor line. Monitor lines cannot span holes in the mesh. | ||

| Line 278: | Line 333: | ||

| 157 | | 157 | ||

| forrtl: severe (157): Program Exception - access violation | | forrtl: severe (157): Program Exception - access violation | ||

| Preferences | |||

| SMS failed to locate the SRH-Pre executable. | | SMS failed to locate the SRH-Pre executable. | ||

| Review the file location in the ''Preferences'' dialog to ensure it is set to the correct location for SRH-Pre. | | Review the file location in the ''Preferences'' dialog to ensure it is set to the correct location for SRH-Pre. | ||

| Line 284: | Line 340: | ||

| | | | ||

| MESH-UNIT: Enter one of the following options for the unit of the mesh. | | MESH-UNIT: Enter one of the following options for the unit of the mesh. | ||

| Projections | |||

| There is an issue with the units set for the project. SRH requires that vertical and horizontal units be in either meters or U.S survey feet. | | There is an issue with the units set for the project. SRH requires that vertical and horizontal units be in either meters or U.S survey feet. | ||

| Review the project and mesh project and units. | | Review the project and mesh project and units. | ||

| Line 290: | Line 347: | ||

| 1 | | 1 | ||

| Stopped in add_nbdf.90 DIS | | Stopped in add_nbdf.90 DIS | ||

| BC Coverage | |||

| Issue with the boundary conditions arcs. | | Issue with the boundary conditions arcs. | ||

| In this case, this issue was from a bug where SMS was exporting the nodestring in the SRHGEOM file incorrectly for two HY8 culvert arcs. SMS was essentially writing the same string of nodes for both the upstream and downstream culvert arcs.--> | | In this case, this issue was from a bug where SMS was exporting the nodestring in the SRHGEOM file incorrectly for two HY8 culvert arcs. SMS was essentially writing the same string of nodes for both the upstream and downstream culvert arcs.--> | ||

| Line 296: | Line 354: | ||

| | | | ||

| Could not find a mesh cell which contains the monitoring point! Check the input of (X Y) coordinates for a monitoring points | | Could not find a mesh cell which contains the monitoring point! Check the input of (X Y) coordinates for a monitoring points | ||

| Monitor Coverage | |||

| A monitor point is outside of the mesh domain. | | A monitor point is outside of the mesh domain. | ||

| Adjust the monitor point to be somewhere within a mesh element. | | Adjust the monitor point to be somewhere within a mesh element. | ||

| Line 302: | Line 361: | ||

| 4 | | 4 | ||

| Program stopped due to the following: Stopped in sec_blow NLAY Error Code is: 4 | | Program stopped due to the following: Stopped in sec_blow NLAY Error Code is: 4 | ||

| Model Control | |||

| This errors occurs when sediment transport is on and there are more than the maximum number of allowed sediment layers (9) for one or more sediment materials. | | This errors occurs when sediment transport is on and there are more than the maximum number of allowed sediment layers (9) for one or more sediment materials. | ||

| Reduce the number of sediment layers to 9 or less for each sediment material. | | Reduce the number of sediment layers to 9 or less for each sediment material. | ||

| Line 312: | Line 372: | ||

! style="width:5%;" | Error Code | ! style="width:5%;" | Error Code | ||

! style="width:25%;" | Error Text from Model | ! style="width:25%;" | Error Text from Model | ||

! style="width:5%;" | Affected Model Component | |||

! style="width:25%;" class="unsortable" | Description | ! style="width:25%;" class="unsortable" | Description | ||

! style="width: | ! style="width:35%;" class="unsortable" | Potential Solution | ||

<!-- Use the following as a template to add new entries | <!-- Use the following as a template to add new entries | ||

|- | |- | ||

| Line 326: | Line 387: | ||

| | | | ||

| No mesh that matches the scalar set. | | No mesh that matches the scalar set. | ||

| 2D Mesh | |||

| No mesh that matches the scalar set. The solution file does not correspond to the mesh in the project, or node numbering of the mesh has been changed, invalidating the solution. | | No mesh that matches the scalar set. The solution file does not correspond to the mesh in the project, or node numbering of the mesh has been changed, invalidating the solution. | ||

| Take care when making edits to the mesh and renumbering the nodes. Any previous results will be invalidated when nodes are renumbered. | | Take care when making edits to the mesh and renumbering the nodes. Any previous results will be invalidated when nodes are renumbered. | ||

| Line 332: | Line 394: | ||

| None | | None | ||

| None | | None | ||

| 2D Mesh | |||

| WSE error directly under the bridge in the form of waves oscillating through the channel. | | WSE error directly under the bridge in the form of waves oscillating through the channel. | ||

| Use larger, quadrilateral elements in the deepest areas of flow. Lowering the time step may also help. | | Use larger, quadrilateral elements in the deepest areas of flow. Lowering the time step may also help. | ||

| Line 339: | Line 402: | ||

| None | | None | ||

| None | | None | ||

| BC Coverage | |||

| SRH-2D is not recognizing a 1D structure or 2D pressure flow structure. When reviewing the 2D results or output files it does not appear that SRH-2D is using a structure such as a culvert, pressure flow bridge structure, weir, or gate. | | SRH-2D is not recognizing a 1D structure or 2D pressure flow structure. When reviewing the 2D results or output files it does not appear that SRH-2D is using a structure such as a culvert, pressure flow bridge structure, weir, or gate. | ||

| Make sure the pair of arcs in the SRH-2D boundary condition coverage representing the faces of the structure were created in the same topologic direction (i.e. both were created left to right looking downstream or both were created right to left downstream). The direction does not matter, only that both arcs are consistent. Turn on the display of arc "Direction" in the display options for the map arcs. This will add an arrow to the map arcs in the display denoting their topologic direction. | | Make sure the pair of arcs in the SRH-2D boundary condition coverage representing the faces of the structure were created in the same topologic direction (i.e. both were created left to right looking downstream or both were created right to left downstream). The direction does not matter, only that both arcs are consistent. Turn on the display of arc "Direction" in the display options for the map arcs. This will add an arrow to the map arcs in the display denoting their topologic direction. | ||

| Line 345: | Line 409: | ||

| | | | ||

| The following coverage(s) have an unsupported type and will be converted to area property: ''(Name of Coverage(s) Listed)'' | | The following coverage(s) have an unsupported type and will be converted to area property: ''(Name of Coverage(s) Listed)'' | ||

| When opening the | | Files | ||

| When opening the SRH-2D map file without the accompanying project file, the SRH-2D map coverages were not recognized. | |||

| If the coverage type is under Model (which the *.map file provided indicated it was) then the type is stored in the project file so that error will appear when opening the *.map file. Locate and open the project file instead of the *.map file. | | If the coverage type is under Model (which the *.map file provided indicated it was) then the type is stored in the project file so that error will appear when opening the *.map file. Locate and open the project file instead of the *.map file. | ||

|- | |- | ||

| Line 351: | Line 416: | ||

| 1 | | 1 | ||

| Error code 1 | | Error code 1 | ||

| Materials Coverage, Export | |||

| *.srhmat file does not exist. | | *.srhmat file does not exist. | ||

| File didn't export successfully. Make sure materials are assigned in the materials coverage. | | File didn't export successfully. Make sure materials are assigned in the materials coverage. | ||

|} | |} | ||

==Examples== | |||

A few examples of projects containing errors are included here. | |||

===Example 1=== | |||

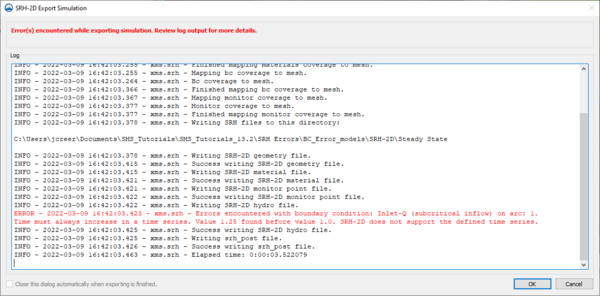

This example shows an SRH-2D project where the inflow boundary condition arc has an incorrect entry in the time series for the boundary condition properties. | |||

Download the sample files [[Media:SRH BC Error models.zip|here]]. Review the inflow boundary condition attributes, including the ''XY Series'' editor. Run the simulation to see the error. | |||

[[File:BC ErrorsPre.png|thumb|none|600 px|Example of an SRH-2D project with incorrect boundary conditions]] | |||

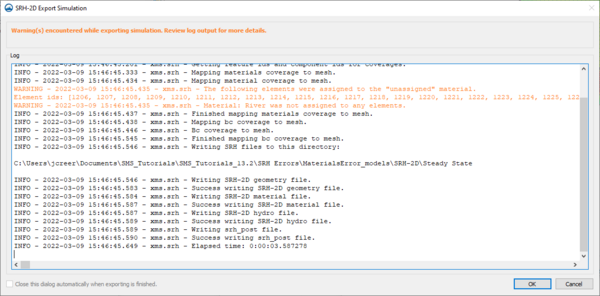

===Example 2=== | |||

This example shows an SRH-2D project where a material has been incorrectly left unassigned. | |||

Download the sample files [[Media:SRH MaterialsError.zip|here]]. Review the materials coverage to see the unassigned material. Run the simulation to see the error. | |||

[[File:MaterialsErrorPre.png|thumb|none|600 px|Example of an SRH-2D project with incorrect materials]] | |||

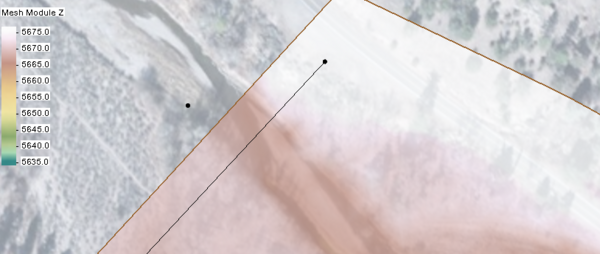

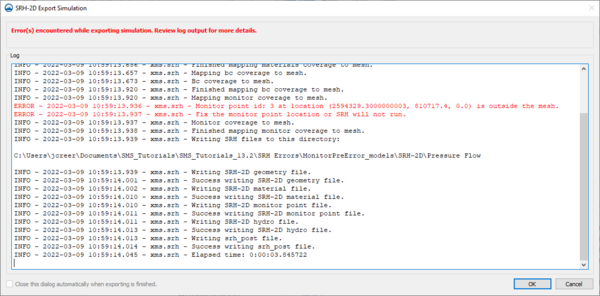

===Example 3=== | |||

This example shows an SRH-2D project where a monitor point have been created outside of the mesh domain. | |||

Download the sample files [[Media:SRH MonitorPreError.zip|here]]. Review the monitor coverage to locate the point that is outside the mesh domain. Run the simulation to see the error. | |||

[[File:Monitorpointoutsidedomain.png|thumb|none|600 px|Example of an SRH-2D project with a monitor point outside the domain]] | |||

[[File:Monitorpointerror.png|thumb|none|600 px|Example of an SRH-2D project with an incorrect monitor point]] | |||

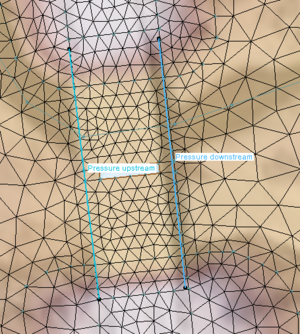

===Example 4=== | |||

This example shows an SRH-2D project where area between the pressure arcs has been left with a paved (triangular) elements. | |||

Download the sample files [[Media:SRH PressurePavedError.zip|here]]. Review the 2D mesh in the location of the pressure bridge. Run the pressure simulation to see the error. | |||

{|- | |||

|- | |||

|[[File:PressurePavedError.png|thumb|none|300 px|Example of an error caused by having a paved mesh in a pressure structure]] | |||

| | |||

[[File:PressurePavedMeshError.png|thumb|none|300 px|Paved mesh between pressure arcs]] | |||

|} | |||

===Example 5=== | |||

This example shows an SRH-2D project where, in the ''Model Control'', a restart file has been selected. After adding the restart file, changes were manually made to the 2D mesh resulting a mismatch. | |||

Download the sample files [[Media:SRH RestartError.zip|here]]. Review the model control and restart file. Run the simulation to see the error. | |||

[[File:SRH2D RestartError.png|thumb|none|300 px|Example of an error caused by restart file that does not match the 2D mesh]] | |||

==Related Topics== | ==Related Topics== | ||

* [[SMS:SRH-2D|SRH-2D]] | * [[SMS:SRH-2D|SRH-2D]] | ||

* [[SMS: | * [[SMS:Release Notes SMS|SMS Release Notes]] | ||

Latest revision as of 18:02, 3 July 2024

This is a list of common known error messages produced by SRH-2D. This is not a comprehensive list of all possible errors. These errors will appear during the model run.

- NOTE: To search this web page, use CTRL+F

An error may occur during either the Pre-SRH-2D process or during the SRH-2D process. During the run, errors will be listed in the SRH-2D model wrapper. Clicking the PreSRH-2D button in the model wrapper will display results from the pre-processor. Clicking the SRH-2D button will show results from the model run.

If the model wrapper has been closed, two files are generated recording the model run. Opening the "*_.OUT.dat" or the "*_DIA.dat" files in a text editor will show errors in the model run.

List of Error Messages

The first three columns in the table are sortable. Simply click the small arrows on the right side of the column header to sort in ascending or descending order.

The columns in the table include:

- Location indicates whether the error occurs in the SRH-2D Pre-processor or in SRH-2D itself.

- Error Code gives the Error Code (if any).

- Error Text from Model gives the full text of the error message. Errors that do not produce any error text will have "no text" in this field.

- Affected Model Component gives the component(s) in the model which is most likely causing the error and will need review/adjustment for the simulation to run correctly.

- Description gives more details about the error.

- Potential Solution gives steps that may be necessary to correct the issue.

SRH-2D Simulation Errors

This table lists errors that can occur during the SRH-2D simulation run.

| Location | Error Code | Error Text from Model | Affected Model Component | Description | Potential Solution |

|---|---|---|---|---|---|

| SRH-2D | 1 | Stopped in spline.f90 H | BC Coverage, Materials Coverage | Time series data used to define inflows/outflows, time varying water surface elevations, or time varying roughness has issues with how it is defined, such as duplicate times. | The time series data should only have one data value per defined time. Review the XY Series Editor where the time series data is defined for the boundary conditions and remove any duplicate time entries. |

| SRH-2D | 1 | Stopped in uti_qwin_xyplot.f90 TIME_SIMU | Model Control | Inconsistent time control settings. | The end time is prior to the start time in the model control. Adjust so the end time is later than the start time. |

| SRH-2D | No cells cover an obstruction in structure_obstruction.f90 | Obstruction Coverage | Obstruction feature area of influence does not cover the centroid of at least one element. | The "Obstruction Width/Diameter:" value in the Obstructions Properties dialog is set to "0" and/or an obstruction arc is positioned just beyond half the width/diameter defined in the properties from the centroid of a mesh element. | |

| SRH-2D | 5 | Stopped in structure_culvert.f90 ICELL error#5 | Material Coverage | Boundary condition arc mesh snapping does not match inactive material zone snapping. | Review the material polygon snapping and review material assignment. |

| SRH-2D | 5 | Stopped in structure_culvert.f90 ICELL | Boundary Condition Coverage | HY-8 arc pairs are not lining up with each other. | Review the arcs for the culverts. Verify that the arcs are correctly paired and drawn in the same direction. |

| SRH-2D | None | Obstruction Coverage | More than 99 obstructions exist in the project. | SRH-2D has a built in limit to how many obstructions can be included in a model. Currently this limit is 99. Reduce the number of obstructions to 99 or fewer. | |

| SRH-2D | 2 | ALL INLET cells are dry from bc_mdot2.f90! Code may have blow up due to input errors or too-large time step. | Material Coverage | Material polygons near inflow are unassigned. This occurs when the material coverage has not been linked to the simulation. Also occurs when all material polygons covering the inflow BC have an "unassigned" material type. This can also occur if no boundary conditions providing an inflow source have been included in the simulation. | Review the simulation to make certain materials have been assigned and that materials and BC coverages have been added to the simulation. |

| SRH-2D | FATAL ERROR The code diverged; further reduction of time step would help the convergence! | Model Control | Too large of a time step. | Reduce the size of the computational time step in the model control. | |

| SRH-2D | 3 | bad mesh ! Stopped in indx_conn.f | 2D Mesh | Problem in mesh, often due to overlapping elements. | Check if problem cell (element) id is listed. Otherwise, examine mesh quality in SMS. |

| SRH-2D | 0 | Exit code 0 | Varies | The SRH-2D simulation has stopped or finished whether successfully executed or not. | Review the simulation results, if any. Further troubleshooting may be required if there are no solutions data or the data is incomplete. |

| SRH-2D | 8 | Inconsistent cell ID in mesh_connectivity: maybe due to wrong nodestring | 2D Mesh, BC Coverage | There is an issue with how the BC arcs are being assigned to the mesh elements. | Review mesh for overlapping elements. Also, check snapping of BC arcs. |

| SRH-2D | Program Stopped as Mesh is different in RST file One of the following is different: |

Model Control | Using a restart file that was created with another mesh. Restart files can only be used with simulations using the exact same mesh. | Review the restart file and use a restart that matches the mesh. Regenerate the restart file if needed or select a different initial condition option. | |

| SRH-2D | 6940 | None | Material Coverage | The assigned material types for the areas upstream or downstream of the culvert location are not valid. | Ensure that areas upstream of the upstream culvert location and areas downstream of the downstream culvert location have a valid material type assigned. |

| SRH-2D | 1 | Stopped in structure_pressure_flow.f90 PARA DISTANCE | 2D Mesh, BC Coverage | Shape of pressure zone is not acceptable for a parabolic type bridge ceiling. | Ensure that the pressure zone, between the pressure flow arcs, is rectangular in shape. |

| SRH-2D | 9669 | Program stopped due to the following:

Wrong IFACE matching occurred in structure_internal.f90 #4 Error Code is: 9669 |

2D Mesh, BC Coverage | The area between the pressure zone arcs with overtopping turned on is not rectangular in shape and/or that the elements in-between the arcs are not rectangular. | Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). If necessary, create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. |

| SRH-2D | 46631 | Program stopped due to the following:

Wrong IFACE matching occurred in structure_internal.f90 #4 Error Code is: 46631 |

2D Mesh | Ensure that the area between the pressure zone arcs with overtopping turned on is rectangular in shape and that the elements in between the arcs are quads (rectangles). | Create a new mesh with a rectangle between pressure flow arcs and which has quads in this area using the patch mesh generation method. |

| SRH-2D | 0 | Program stopped due to the following:

Wrong IFACE matching occurred in structure_internal.f90 #4 Error Code is: 0 |

BC Coverage | There is an issue with one or more boundary condition arc definitions. | Review snap preview of boundary condition arcs. |

| SRH-2D | 16026 | Program stopped due to the following:

A downstream Structure nodestring has not set right; structure_culvert.f90 ICELL error#2 Error Code is: 16026 |

2D Mesh | The 2D mesh around and through the structure is not optimal. | Examine the areas around the structure. Suggestions to optimize the mesh around the structure include creating patched (quadrilateral) elements through the structure from one face to the other. |

| SRH-2D | 79 | Program stopped due to the following:

Tailwater WSE exceeded the maximum TW in the Reverse HY8 Table structure_hy8.f90 Error Code is: 79 |

2D Mesh, Model Control | Computed water surface elevations near the culvert became extremely high. This could be from too large of a time step, poor mesh quality near the culvert faces, or parts of the mesh were the culvert is applied have higher elevations than what are defined as the inverts defined in the HY-8 culvert definition | Review mesh quality near the culvert face. Check to ensure that mesh node elevations where culvert faces are applied do not exceed invert elevations as defined in the HY-8 culvert definition. Lowering the time step to improve stability around the culvert could also help. |

| SRH-2D | N/A | forrtl: severe (24): end-of-file during read, unit n, file {your filepath.dat} Image PC Routine Line Source srh2d_3.2_quickwi...Unknown... | Varies | This is usually a generic error indicating something is wrong with the SRH-2D simulation casename.DAT file created by SRH pre. It typically signifies that SRH-Pre did not terminate normally and generate a valid simulation file. The cause of the error could be any number of issues. | Check for any error messages reported by SRH-pre by going to the SMS model wrapper and clicking on the "PreSRH-2D" line and reviewing the on screen output messages. |

| SRH-2D | N/A | Failed to find a mesh cell which contains the following (x y) points: (X,Y)= | 2D Mesh | This is caused when there is a void added to the mesh by deleting a mesh element from the mesh after the mesh has been generated. Creating void by deleting mesh elements may not actually remove the element data from the mesh in SRH-2D. | If a void is needed in the mesh, it should be created as a polygon in the Mesh Generator coverage and given a mesh type of "None". When a mesh is generated using polygons with the "None" type, a void will be created in the mesh that can be recognized by SRH-2D. |

| SRH-2D | 0 | Program stopped due to the following: IFACE match does not found in structure_culvert.f90 #n | 2D Mesh | Element configuration around the structure face is causing a mismatch in the transition into or out of the structure. | It may help to ensure all elements within the two structures are quadrilateral elements. It may also help to ensure that the first row of elements downstream of the downstream structure face and upstream of the upstream structure face are also quadrilateral elements that are "well formed" ("Well formed" elements as in having interior corners as close to 90 degrees as possible). |

| SRH-2D | 1 | Program stopped due to the following: Stopped in read_input2.f90 HY8 Forward_TABLE Line Error | Files | There is a problem reading the culvert table file. One of the causes of this is that the HY-8 file containing the culvert definition does not include a file extension. | Add a ".hy8" file extension to the culvert definition file name. |

| SRH-2D | N/A | forrtl: severe (170): Program Exception - stack overflow | 2D Mesh | The simulation is too large for SRH-2D to process. Typically this occurs when running a simulation using sediment transport and a 2D mesh that contains more than 50,000 elements. | Reduce the number of elements in the 2D mesh and try running the simulation again. |

| SRH-2D | 3 | Not ready in solve.f90 SEDIMENT MODULE | Model Control, BC Coverage | This errors occurs when sediment transport is being modeled in a project containing 1D hydraulic structures (culverts, weirs, pressure bridges, etc.). SRH-2D cannot model sediment transport in models containing 1D hydraulic structures. | Either do not use the sediment transport in the model run, or remove the 1D hydraulic structures from the model. |

| SRH-2D | 1 | Program stopped due to the following: Wrong Boundary ID;may due to some boundary mesh points are not in NODESTRING lists in SMS | 2D Mesh | This error seems to be related to issues with mesh quality. | Review mesh quality. Check for elements with very small or very large interior angles (angles less than 10 degrees or greater than 180 degrees. If any are present, make adjustments in the conceptual model (mesh generator coverage) and re-generate the mesh. |

| SRH-2D | 67 | Input statement requires too much data, unit 1 | Model Control | This error appears related to using a restart file that doesn't match the project geometry. | Review the restart file. Common issues appear to be using a restart file that came from a different project or uses a different projection. Check that all major aspects of the project geometry (mesh, nodes, units, coordinate system) match what is used in the project in order to use a restart file. The other solution is to not use a restart file with the simulation and select another option for the initial condition. |

| SRH-2D | 7 | Inconsistent cell ID in mesh_connectivity.f90: maybe wrong nodestring | BC Coverage | This error is caused when two arcs in the boundary condition coverage snap to the same nodes but have different boundary condition types. | Review the boundary condition arcs and use the snap preview. |

| SRH-2D | 16 | Linked Pair nodestring direction is wrong; please reverse them. | BC Coverage | This error is caused when a paired arc structure, such as a culvert, has arcs that have been drawn in opposite directions or the arcs are not facing downstream. | Review a paired arc structures to ensure that the arcs are post going the same direction and that the arcs are facing downstream. Fix any structure arcs that are going the wrong direction. |

| SRH-2D | 4 | Program stopped due to the following: The upstream INTERNAL boundary linked to a downstream should a water withdrawal! | BC coverage or 2D mesh | This indicates a model instability near a boundary condition arc. Review 2D mesh elements near BC arcs and/or adjust BC coverage values. |

Pre-SRH-2D Simulation Errors

This table contains errors that can occur during the PreSRH-2D, or pre-processor, run for the simulation.

| Location | Error Code | Error Text from Model | Affected Model Component | Description | Potential Solution |

|---|---|---|---|---|---|

| PreSRH-2D | 1 | unable to open srhhydro file! | Files | Unable to open the exported srhhydro file. | The path length for the SMS project is too long. Therefore, the SRH-2D preprocessor could not read the exported files from SMS. Reduce the path length to less than 300 characters. |

| PreSRH-2D | 1 | Element ID is not consecutive | 2D Mesh | The mesh element ID's have been mismatched since some mesh nodes were modified and not renumbered. | Renumber the mesh nodes using the Renumber command under the Nodes menu in the Mesh module. |

| Pre SRH-2D | Errors from final_touch.f90 **** on MONITOR LINE#n a face cannot be found given two mesh points Two points are: xx xx |

Monitor Coverage | Monitor line spans a void or hole in the mesh. | Reconfigure the monitor line. Monitor lines cannot span holes in the mesh. | |

| PreSRH-2D | 157 | forrtl: severe (157): Program Exception - access violation | Preferences | SMS failed to locate the SRH-Pre executable. | Review the file location in the Preferences dialog to ensure it is set to the correct location for SRH-Pre. |

| PreSRH-2D | MESH-UNIT: Enter one of the following options for the unit of the mesh. | Projections | There is an issue with the units set for the project. SRH requires that vertical and horizontal units be in either meters or U.S survey feet. | Review the project and mesh project and units. | |

| PreSRH-2D | Could not find a mesh cell which contains the monitoring point! Check the input of (X Y) coordinates for a monitoring points | Monitor Coverage | A monitor point is outside of the mesh domain. | Adjust the monitor point to be somewhere within a mesh element. | |

| PreSRH-2D | 4 | Program stopped due to the following: Stopped in sec_blow NLAY Error Code is: 4 | Model Control | This errors occurs when sediment transport is on and there are more than the maximum number of allowed sediment layers (9) for one or more sediment materials. | Reduce the number of sediment layers to 9 or less for each sediment material. |

Other Errors

This table contains additional errors that can occur with an SRH-2D simulation in SMS.

| Location | Error Code | Error Text from Model | Affected Model Component | Description | Potential Solution |

|---|---|---|---|---|---|

| SMS | No mesh that matches the scalar set. | 2D Mesh | No mesh that matches the scalar set. The solution file does not correspond to the mesh in the project, or node numbering of the mesh has been changed, invalidating the solution. | Take care when making edits to the mesh and renumbering the nodes. Any previous results will be invalidated when nodes are renumbered. | |

| None | None | 2D Mesh | WSE error directly under the bridge in the form of waves oscillating through the channel. | Use larger, quadrilateral elements in the deepest areas of flow. Lowering the time step may also help. | |

| None | None | BC Coverage | SRH-2D is not recognizing a 1D structure or 2D pressure flow structure. When reviewing the 2D results or output files it does not appear that SRH-2D is using a structure such as a culvert, pressure flow bridge structure, weir, or gate. | Make sure the pair of arcs in the SRH-2D boundary condition coverage representing the faces of the structure were created in the same topologic direction (i.e. both were created left to right looking downstream or both were created right to left downstream). The direction does not matter, only that both arcs are consistent. Turn on the display of arc "Direction" in the display options for the map arcs. This will add an arrow to the map arcs in the display denoting their topologic direction. | |

| SMS | The following coverage(s) have an unsupported type and will be converted to area property: (Name of Coverage(s) Listed) | Files | When opening the SRH-2D map file without the accompanying project file, the SRH-2D map coverages were not recognized. | If the coverage type is under Model (which the *.map file provided indicated it was) then the type is stored in the project file so that error will appear when opening the *.map file. Locate and open the project file instead of the *.map file. | |

| SMS | 1 | Error code 1 | Materials Coverage, Export | *.srhmat file does not exist. | File didn't export successfully. Make sure materials are assigned in the materials coverage. |

Examples

A few examples of projects containing errors are included here.

Example 1

This example shows an SRH-2D project where the inflow boundary condition arc has an incorrect entry in the time series for the boundary condition properties.

Download the sample files here. Review the inflow boundary condition attributes, including the XY Series editor. Run the simulation to see the error.

Example 2

This example shows an SRH-2D project where a material has been incorrectly left unassigned.

Download the sample files here. Review the materials coverage to see the unassigned material. Run the simulation to see the error.

Example 3

This example shows an SRH-2D project where a monitor point have been created outside of the mesh domain.

Download the sample files here. Review the monitor coverage to locate the point that is outside the mesh domain. Run the simulation to see the error.

Example 4

This example shows an SRH-2D project where area between the pressure arcs has been left with a paved (triangular) elements.

Download the sample files here. Review the 2D mesh in the location of the pressure bridge. Run the pressure simulation to see the error.

Example 5

This example shows an SRH-2D project where, in the Model Control, a restart file has been selected. After adding the restart file, changes were manually made to the 2D mesh resulting a mismatch.

Download the sample files here. Review the model control and restart file. Run the simulation to see the error.

Related Topics

SMS – Surface-water Modeling System | ||

|---|---|---|

| Modules: | 1D Grid • Cartesian Grid • Curvilinear Grid • GIS • Map • Mesh • Particle • Quadtree • Raster • Scatter • UGrid |  |

| General Models: | 3D Structure • FVCOM • Generic • PTM | |

| Coastal Models: | ADCIRC • BOUSS-2D • CGWAVE • CMS-Flow • CMS-Wave • GenCade • STWAVE • WAM | |

| Riverine/Estuarine Models: | AdH • HEC-RAS • HYDRO AS-2D • RMA2 • RMA4 • SRH-2D • TUFLOW • TUFLOW FV | |

| Aquaveo • SMS Tutorials • SMS Workflows | ||