Template:MODFLOW Grid Overlay

The Grid Overlay option is one of the three basic options for the Solids → MODFLOW command. The Grid Overlay option is similar to the Boundary Matching option. While the Boundary Matching option precisely matches stratigraphic boundaries, it does have some drawbacks. It can result in very thin layers at certain locations in the grid such as transition points at the boundary of a solid that pinches out to a sharp edge. In some cases, these thin layers can cause stability problems with MODFLOW or with a subsequent transport analysis. For such cases, the Grid Overlay method or the Grid Overlay with Keq method may provide superior results.

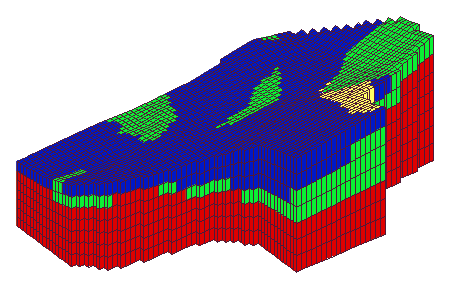

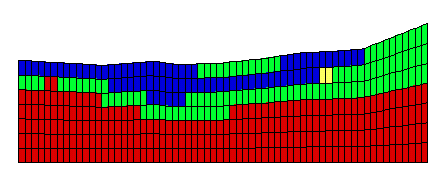

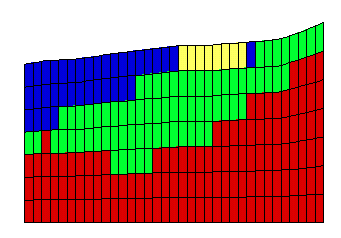

With the Grid Overlay option, no layer range assignments are necessary. Once the solids and grid are created, the Solids → MODFLOW command can be immediately selected. For each vertical column of cells, GMS intersects a vertical ray through the cell center and finds the highest and lowest intersection, i.e. the top and bottom of the entire set of solids. These elevations become the top and and bottom elevation of the entire grid. The elevations of any intermediate layer boundaries are then linearly interpolated between these two extremes. The material properties are then assigned by computing the xyz coordinates of the center of each cell and determining which solid encloses the cell center. The material properties from that solid are then assigned to the cell. The result is shown in the following figure (compare this to the example shown in the Boundary Matching topic). Note that the boundaries of the solids are not preserved as accurately as they are with the boundary matching algorithm. However, the cell sizes are much more consistent and extremely thin cells are avoided.

Minimum Thickness

In some cases, the set of solids used with the Grid Overlay method may have thin sections where the vertical thickness of the entire set of solids becomes extremely small. In such cases, the resulting grid cells become very thin as they are "squeezed" in this thin region. The cell thickness in these regions can be controlled using the Minimum Thickness value in the Solids Attributes dialog. When each vertical column of cells is processed, the height of the cells in the column is compared to the minimum thickness. If the cell height is less than the minimum, one or more cells at the bottom of the grid are inactivated until the minimum thickness is satisfied.